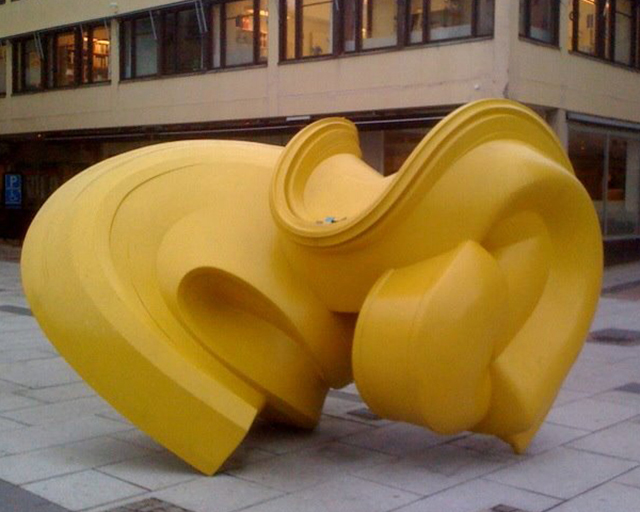

Technological sense of art split surface mirror stainless steel bust sculpture

| Description: | The stainless steel bust sculpture embodies a contradictory nature that seems to capture fluidity within rigid lines, offering a fusion of eternity and ephemerality. As an abstract character, I found resonance in its form – sharp, unyielding edges combined with the intangible concept of the passage of time. Reflective surfaces hold a mirror to the world around them, reflecting not only the natural landscape but also the fleeting emotions and thoughts of those who participate in it. The polished exterior of the stainless steel bust sculpture serves as a canvas for evolving narratives and reflections on the human experience, a silent observer quietly observing the story of passing moments. |

| NO.: | M-(AO26) |

| PRICE | USD$5999 |

| MATERIAL: | Stainless steel #304/ #316. |

| SIZE: | Life-size or custom-made depends on your preference. |

| TECHNOLOGY: | Forging process. |

| PACKING: | Generally soft and waterproof plastic inside, wooden cases/ iron box for outside. |

Stainless steel bust sculpture Details Description:

The stainless steel bust sculpture embodies a contradictory nature that seems to capture fluidity within rigid lines, offering a fusion of eternity and ephemerality. As an abstract character, I found resonance in its form – sharp, unyielding edges combined with the intangible concept of the passage of time. Reflective surfaces hold a mirror to the world around them, reflecting not only the natural landscape but also the fleeting emotions and thoughts of those who participate in it. The polished exterior of the stainless steel bust sculpture serves as a canvas for evolving narratives and reflections on the human experience, a silent observer quietly observing the story of passing moments.

stainless steel bust sculpture

Within the stoic presence of this stainless steel bust sculpture lies a mysterious invitation to explore the depths of identity and the complexity of existence. The bust’s lack of specific facial features invites interpretation, prompting people to question definitions of self and society. The stainless steel bust sculpture is a tribute to the complexity and ambiguity of the human condition – a faceless representation that paradoxically speaks of individuality and universality. As an abstract entity, I am drawn to its ability to evoke a range of emotions – inspiring introspection, curiosity, and ever-changing perceptions.

modern abstract art large bust stainless steel sculpture

This stainless steel bust sculpture embodies through its form and materials a duality that resonates deeply in abstraction. It symbolizes the intersection of the tangible and the intangible, the visible and the invisible, inviting people to explore the boundaries between form and intangibility, perception and transcendence. As an abstract figure, I found myself drawn to the endless possibilities offered by this stainless steel bust sculpture – an invisible vessel and a mysterious reflection of the complexity of existence.

large bust stainless sculpture steel

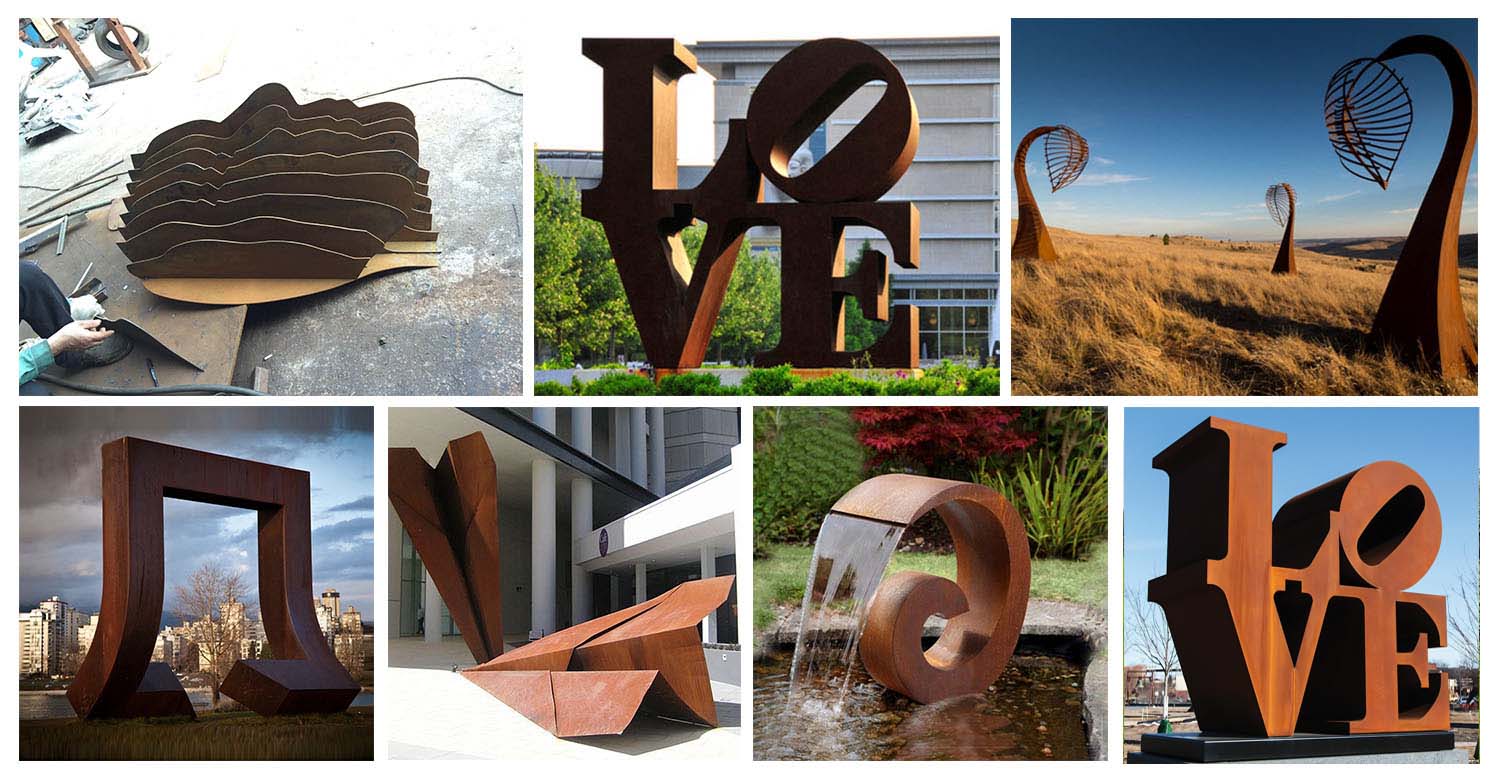

Custom More Stainless Steel Sculpture

Production Flow

| 1. Confirming the design (3D mold/ Pictures/ drawing/ photos). |

| 2. Making exact structures or models according to drawing/ client’s photos/ 3D mold… Modify any details till confirmed. |

| 3. Cover the stainless steel plate on existing structures or models. |

| 4. Welding and polishing the surface. |

| 5. Finished stainless steel sculpture and take all different views pictures/ videos show to clients… |

| 6. Packing into wooden cases and shipping after clients are satisfied with stainless steel sculptures. |

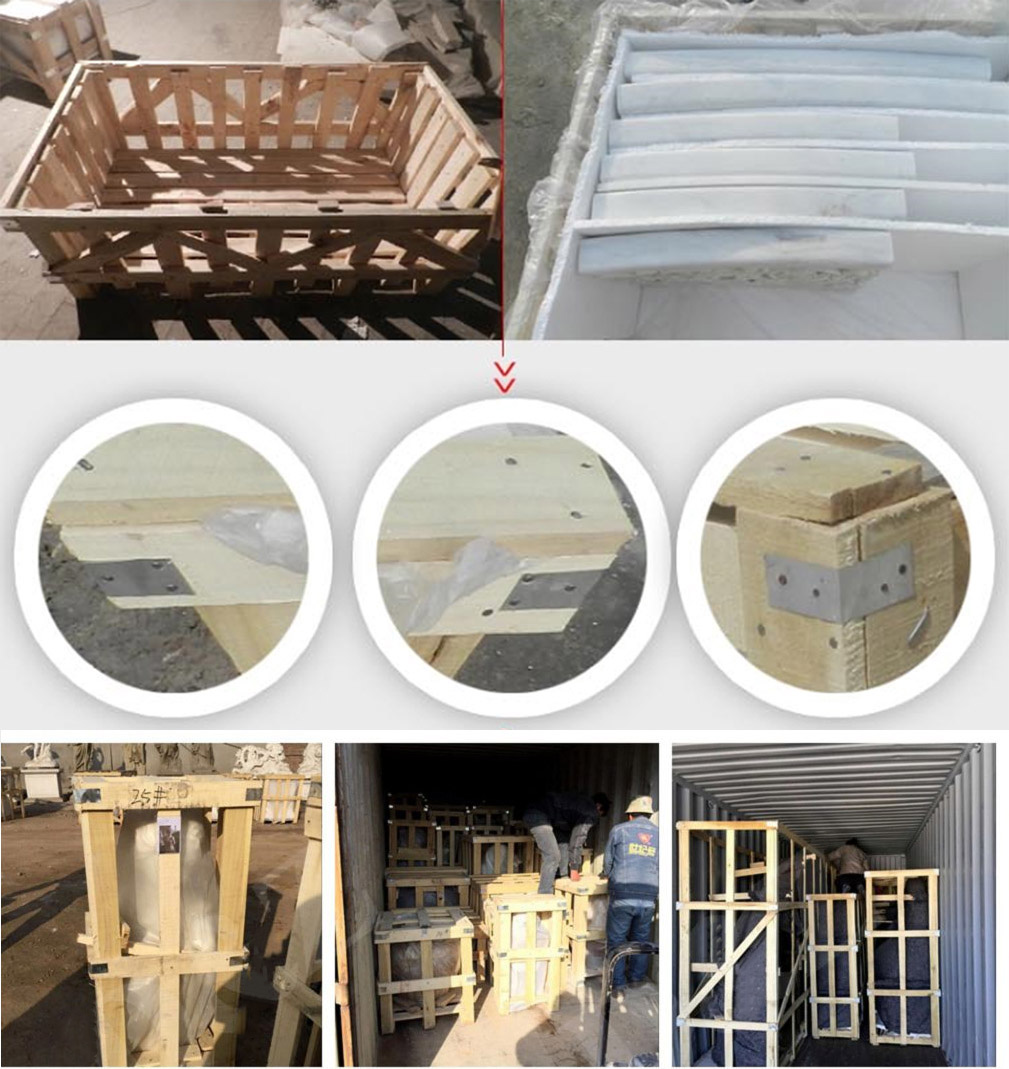

Packaging & Shipping

| Packaging: | Inside: soft plastic foam/ blanket. |

| Outside: strong wooden cases or iron frame boxes. | |

| Shipping: | 1. By sea (Special for life-size sculptures and large sculptures). |

| 2. By air (Special for small sculptures or when clients need the sculpture very urgently). | |

| 3. By express delivery DHL, TNT, UPS, or FedEx. (Door-to-door delivery, about 3-7 days can reach). | |

| 4. Door-to-door service. | |

| Please kindly contact us! We will depend on your sculpture and local situation, find the best delivery way for your reference. | |

Customer Feedback

Leave A Comment