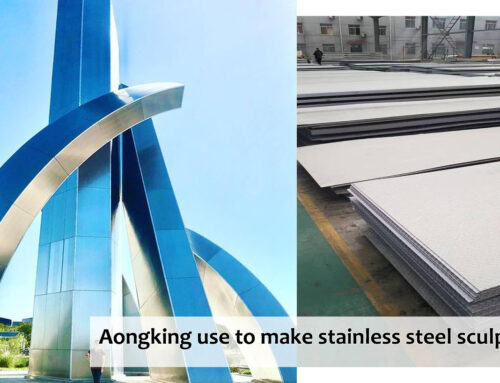

Welding objects have emerged in various artistic processes, making their presence felt in the creation of artworks from multiple perspectives. The intricate journey of the metal art form unfolds such as ‘Sculptural Design,’ ‘Sculptural Framework,’ ‘Sculptural Fusion,’ ‘Sculptural Composition,’ and ‘Sculptural Construction.’. Welding objects of elements represent indispensable components in the crafting of artworks.

1-1: ‘Sculptural Design’ plays a pivotal role in shaping the aesthetics and concepts of the artwork, guiding the artist’s vision. At this stage, welding technology assists in embodying the true existence of the design and provides practical assurance for subsequent processes. Because our design is a drawing and the embodiment of ideas. Welding is the only way to really realize the ideas.

1-2: The creative process begins with material selection and the meticulous design of the ‘artwork framework’, laying the foundation for the fusion of welding elements. Behind the framework there are combinations, and there are links. This also involves welding.

1-3: ‘Sculptural Fusion’ involves the skillful welding and blending of materials, ultimately forming a unified and organic whole. The most intuitive welding expression.

1-4: In ‘Sculptural Composition,’ thoughtful arrangement and interaction of elements contribute to an overarching narrative, conveying a sense of balance and consciousness. The aid of welding is needed, too.

1-5: Subsequently, ‘Sculptural Construction’ concretizes the envisioned design, welding and transforming abstract ideas into tangible forms.

Embarking on an artistic journey, artworks serve as a testament to the creative expression of artists. The casting craftsmanship embedded in sculptural processes reflects the dedication and skill required for shaping and molding. Ultimately, the convergence of metal artwork and its derivatives culminates in sculptural expression—a nuanced and unique interpretation of artistic vision, inviting viewers to immerse themselves in the depth and meaning inherent in each sculptural creation.

‘Sculptural Construction’ concretizes the envisioned design